In recent years, the rapid development of the service and industrial sectors has aimed to meet the growing demands of the economy, including the construction materials industry in general and the paint industry in particular, especially the water-based paint manufacturing sector.

According to statistical data, there are an estimated over 500 water-based paint production facilities nationwide, producing a wide variety of brands, often without proper oversight from regulatory authorities. While regulations on chemical management in this field exist and are comprehensive, coordination among relevant agencies is often lacking. This has led to a situation where the final products vary greatly in type and quality, affecting the durability of construction works, consumer health, and environmental safety and hygiene.

This article focuses specifically on the current state of water-based paint production in Vietnam and provides solutions for choosing products that are safe for consumers.

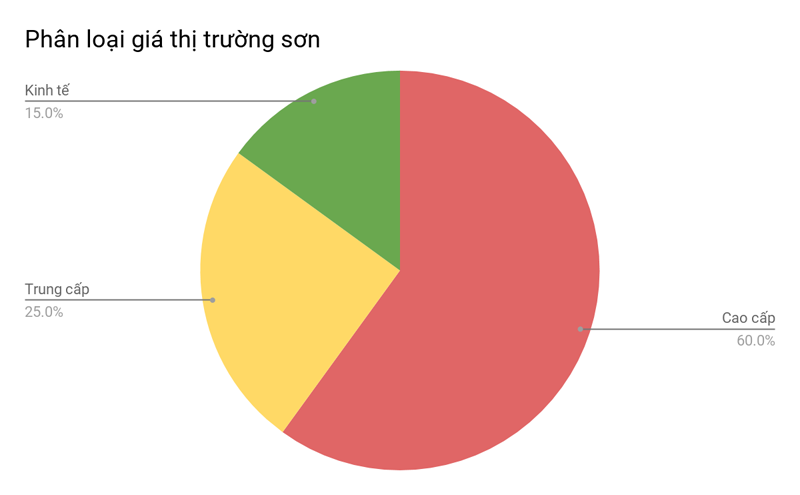

Phân loại giá thị trường sơn –

Water-based paint, often called emulsion paint or decorative paint, is commonly used as a protective and finishing coating in construction projects. Like other building materials, it is regulated according to specific standards and technical regulations. Before being marketed, paint products must have their quality declared and approved by the relevant management authority, typically the local Department of Construction where the production facility is located.

However, nowadays, most production facilities operate spontaneously, ignoring strict regulations on chemical safety and usage in this sector. For example, production facilities must comply with environmental regulations: facilities producing less than 80 tons of paint per year are required to develop chemical incident prevention measures and commit to environmental protection. Facilities producing more than 80 tons per year must prepare an environmental impact assessment report and obtain approval from provincial authorities and relevant departments. In addition, production facilities must register for chemical management and usage, and implement chemical incident prevention measures with the Department of Industry and Trade. Fire prevention measures and many other legal requirements are often ignored, leading to unhealthy competition and posing significant risks to consumer health.

In paint production, selecting environmentally friendly raw materials is extremely important, as it affects not only consumer health but also construction quality, air quality, and water quality. Currently, the market offers a wide range of imported chemicals with various origins and qualities. Information on chemical safety and product quality is often vague, making it difficult for non-experts to choose safe products. In countries such as the USA, Japan, Germany, and Singapore, regulations on chemical usage in paint are strict, clearly specifying which chemicals are allowed.

VOC content is a major concern. According to the U.S. Environmental Protection Agency (EPA), 9% of environmental pollutants are caused by VOCs released from paints. All paints contain four main components: extenders, binders, additives, and solvents. Among these, solvents and additives are the primary sources of VOC emissions.

Many global studies have shown that certain chemicals in low-quality paints can adversely affect fetal development. People may experience allergies, headaches, dizziness, eye irritation, and breathing difficulties upon exposure. According to the American Lung Association, VOCs can cause eye and skin irritation, respiratory and lung problems, headaches, dizziness, muscle weakness, and even liver and kidney damage. Consequently, increasing societal concern for health and well-being has influenced the construction industry, leading to the growing trend of “green buildings.”

In Vietnam today, many paints harmful to health and the environment are still used for houses, workplaces, high-rise buildings, and luxury apartments. These include paints with very high VOC content, such as oil-based paints, polyurethane (PU) paints, and nitrocellulose (NC) paints. Even well-known brands continue to produce oil-based or harmful water-based paints that contribute to environmental pollution.

Studies indicate that indoor VOC levels can be ten times higher than outdoor levels, and in some cases may increase by over 1,000 times after a fresh coat of paint is applied. This highlights the importance of choosing paints not only for aesthetic appeal but also for health and safety, particularly for the elderly, children, and expectant mothers.

In water-based paints, VOCs are present in binders, film-forming additives, anti-mold agents, and preservatives. Unfortunately, very few manufacturers consider this factor. Another concern affecting human living environments is that many production facilities fail to comply with Vietnamese technical standards for product quality, such as adhesion, hardness, viscosity, and VOC limits. As a result, protective paint films are of poor quality, leading to chalking and the release of significant amounts of organic and inorganic dust into the environment, impacting human health and surrounding water sources.

Currently, many condominiums, office buildings, and government projects still use these low-quality products despite their high budget allocations. ASA Group advises customers to make informed choices, selecting high-quality, safe, and environmentally friendly paint products for their health, their family’s well-being, and the community.